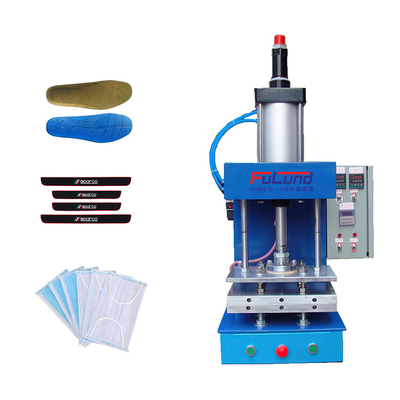

Nike Aj Adidas Pneumatic small hot press Desktop pneumatic hot press Leather label hot press

Fulund has a long history since its establishment in 1999. Due to the needs of development, the original brand (TYL) expanded the new brand Fulund in 2022 . Fulund has customers all over the world,such as international brands shoe manufacturer.

Fulund mainly products: Hot label machine, foam cutting machine, insole hot stamping machine, shoe tongue transfer hot stamping machine, insole heat transfer machine, insole cutting and transfer integrated machine, insole printing machine, silk screen printing machine, embossing machine, soft rubber equipment , vacuum vulcanizing machine, silicone labeling machine, glue dispensing machine, etc.

What is hot foil stamping machine

The pictures and texts stamped on anodized aluminum show a strong metallic luster, and the colors are dazzling and never fade.

In particular, gold-silver anodized aluminum decorates the surface of the printed matter with its splendid, exquisite and elegant decoration, enhances the artistry of the printed matter, and plays a role in promoting the theme; Stamped with silver, the product has a high-end feel and a beautiful enjoyment.

At the same time, because anodized aluminum has excellent physical and chemical functions, it plays a role in protecting printed products, so the hot stamping process is widely used in high-end, exquisite packaging and decoration trademarks, calendars and book covers and other printed materials Second, the range of anodized aluminum hot stamping is very wide, from general book covers, trademark drawings, publicity advertisements, plastic products to daily necessities, from paper to leather, cotton, etc.; A dry processing method, the workpiece can be packaged and transported immediately after being ironed. Therefore, hot stamping technology is now widely used, and the scope of application of hot stamping is still expanding.

Features of heat press machine:

1. Powered by compressed air, the descending speed is adjustable

2. Mini table C type model

3. The adjustable stroke of the cylinder is easy to adjust, and the downward speed of the cylinder is adjustable

4. The mechanical start method has a double button switch (or optional foot switch) design

5. The cylinder is equipped with anti-rotation double guide rods to make the work more accurate; in addition, the output of the cylinder can be adjusted by the pressure regulating valve

6. The upper and lower molds have heating function (for hot pressing, stamping, branding, bronzing, printing, etc.)

7. Use pressure (air pressure): 4-7KG/square centimeter Maximum mechanical stroke: 120MM adjustable 50MM

8. Adjustable temperature: normal temperature -250 degrees, adjustable up and down independent temperature control Mechanical appearance: W400*D600*H500MM

9. Hot pressing time: 0.01S-99.99H can be adjusted arbitrarily; heating plate area: 200*300MM (size can be customized)

10. Power of the whole machine: 5KW Power supply voltage: 380/220V (single-phase) Mechanical weight: 70KG

Hot press setting machine parameters

1. Automatic constant temperature,

2. Automatic timing

3. Automatic counting

4. C frame construction

5. Double start switch

| Heating plate area | 200MM*300MM | 300MM*400MM |

| Temperature regulation | Room temperature~300°C can be adjusted arbitrarily | Room temperature~300°C can be adjusted arbitrarily |

| Temperature control | Automatic constant temperature | Automatic constant temperature |

| temperature accuracy | ±2℃ | ±2℃ |

| Air pressure | 0.4-0.7Mpa | 0.4-0.7Mpa |

| power supply | AC220V±5% 50/60HZ | AC380V±5% 50/60HZ |

| Power | 3.6KW | 5.6KW |

| Hot pressing time | 0.1S~99.99H | 0.1S~99.99H |

| Mechanical pressure | 300KG -800KG Adjusted | 300KG -800KG Adjusted |

| cylinder can adjust the distance | 50MM | 50MM |

| host volume | 550×480×960MM | 650*500*980MM |

| Upper and lower mold distance | 150MM | 150MM |

| weight | 90KG | 130KG |

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()